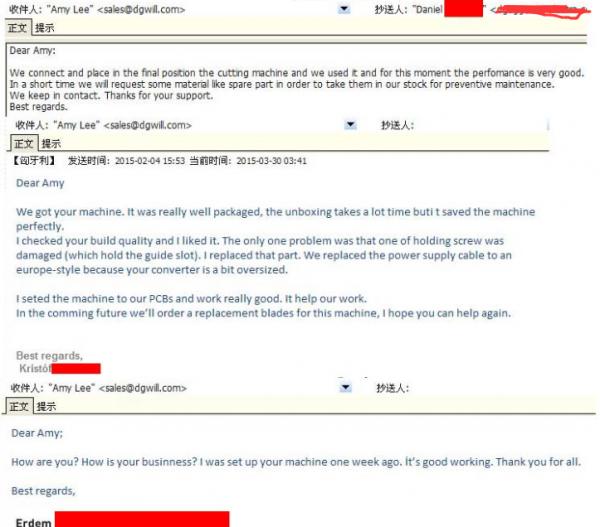

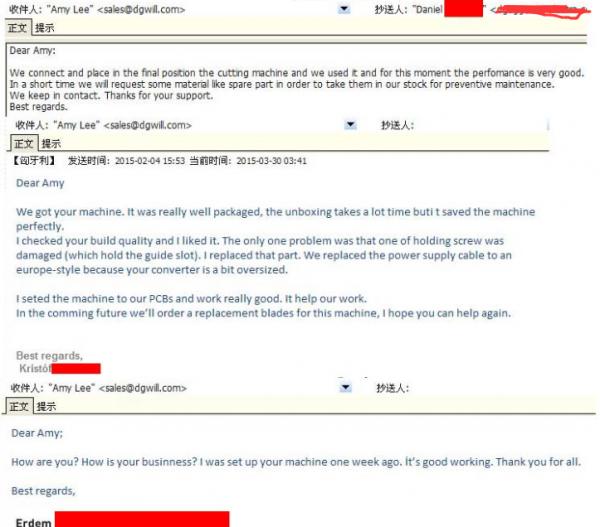

Customer Feedback

Technical parameters:

1 Power supply: AC220V ± 10%, 50Hz, 3500W

2 Work environment :10-60 ℃, 40% ~ 95%

3 Working pressure: 0.5 ~ 0.7Mpa

4 Welding pressure: 2.5 ~ 28Kgf

5 Temperature settings: three sections (including start /

separation)

6 Temperature settings: RT ~ 450 ℃

7 Pressing time: 1 ~ 99 s

8 Hot Accuracy: pitch 0.14mm

9 Production capacity: 220pcs / h

10 Hot Head size: MAX 50 × 8mm

11 Dimensions: approx (L) 500mm × (W) 700mm × (H) 810mm

12 Weight: about 120KG

Features:

1. PLC control system, pulse heating, hot head with titanium to

achieve rapid warming. Rapid cooling, temperature control and

accurate.

2. Duplex rotation rotation feeding, enhance efficiency.

3. The on-bit dual camera system.

4. Optional touch screen control functions.

Uses: Suitable for all kinds of ordinary TAB, TCP crimping, and

FPC, FFC and PCB solder crimp.

Customer list:

Production process;

Our service:

1. Engineers available to service machinery oversea

Engineers are available to be sent to freign countries to do

machinery training and offer technical support.

2. Mature technique & forerunner to process makes high quality

machinery

As largest manufactory in South China, we have 12 years experience

on PCB separator machines and soldering machines.Our R&D team

continuously upgrade the existing machines to meet the market

development trend.

3. Effective customer service

All of us together are stronger and wiser than any one of us

individually. To succeed, we must assume responsibility, cooperate

with fellow associates and withdepartments, effectively comminicate

with one another, foster enthusiam and participate in

decision-making. To be seay reachable by customers and provide

prompt replies to solve their problems and create value for

customers.

4. One year warranty for the machines except accessories

Robust frame construction and Japanese steel blades obtained good

appraise and recognized by and oversea clients. We offer parts for

replacement under warranty free of charge, clients only need to

bear freight charge.

Our mission:

Ongoing PCB industry PCB separator technological innovation, to

create greater value, allowing customers to success

Our Vision:

PCB industry to become the world's leading solution providers PCB

separator